The company is positioned in the market as one of the largest manufacturers of solar panels and is included in the prestigious Tier 1 list compiled by the analytical company Bloomberg. The production of photovoltaic modules is automated and the development of each of the photovoltaic modules goes through a full production cycle – from the formation of silicon crystals to the assembly of the panel. The high quality of the product is confirmed by numerous tests of the company’s internal laboratory, as well as by independent electrotechnical technology standardization centers, such as TUV SUD, ISO, IEC, CE and others.

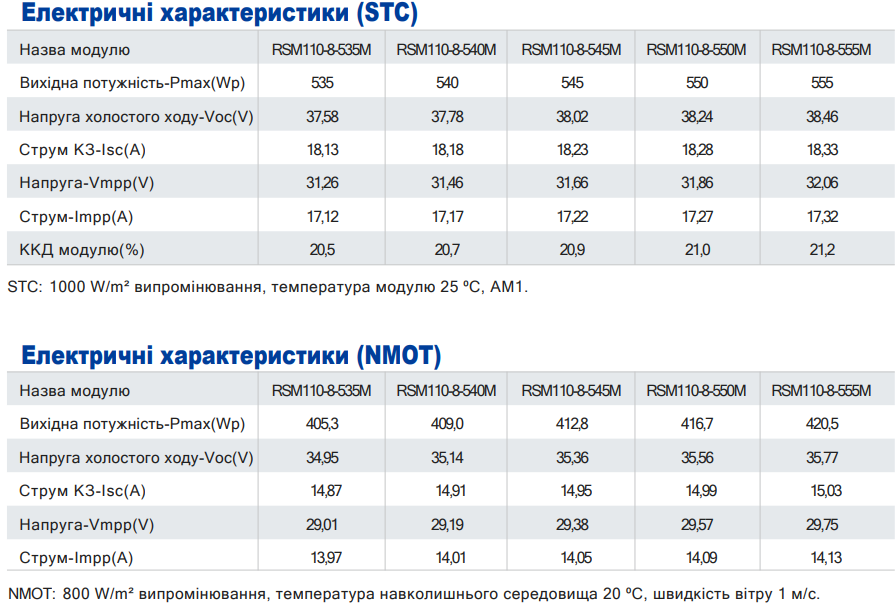

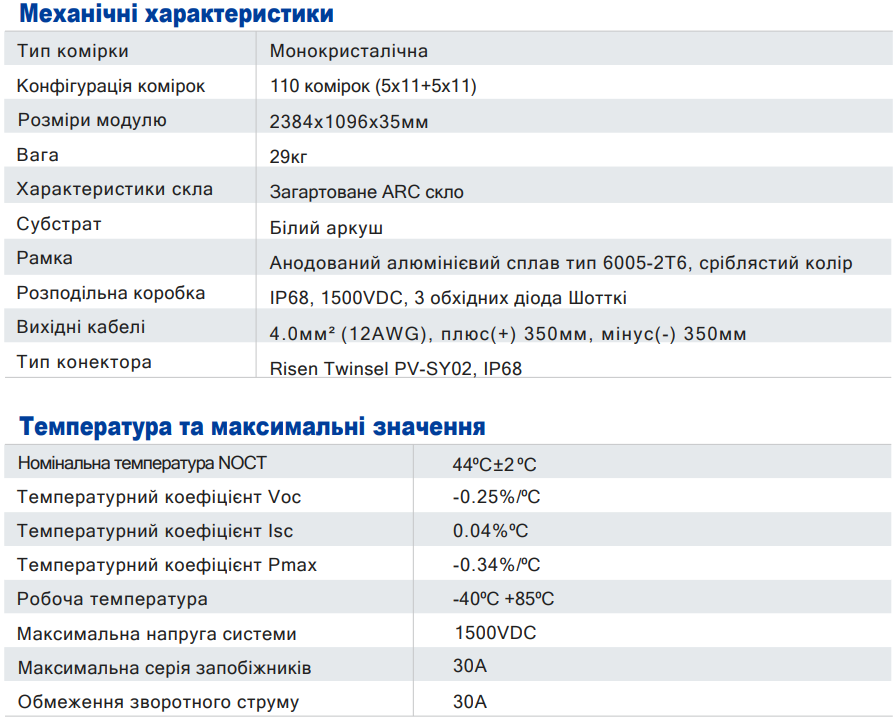

The main feature of the photovoltaic module is a high power of 550 watts. Such a photovoltaic module will allow the owner of the station to place a powerful station in a relatively limited space, save about 10% of his budget on the purchase of modules and reduce the cost of normalized cost of electricity (LCOE) by 6%. The efficiency of the solar panel is 21%, so the panel converts solar energy into electrical energy extremely efficiently. The architecture of the panel is Cut Half-Cell and PERC, which is why this panel is so efficient. The frame of the photovoltaic module is made of aluminum, which undergoes the anodizing process. Therefore, the frame of the photomodule is protected from corrosion. The front part of the photovoltaic module is covered with protective glass 3.2 mm thick, which is resistant to mechanical stress, wind or snow. The photomodule complies with the IP68 protection standard, so dust and moisture cannot get inside the device. The back of the solar panel is covered with EVA film.

The temperature coefficients (power, voltage and amperage) are as follows: for power this value is -0.34%/Co for voltage this value is -0.25%/Co, for current the value of the temperature coefficient is 0.04%/Co. These coefficients determine the percentage loss of each of the characteristics when the photomodule is heated by 1 C o normal (45 C o).